Tailored laser beam shapes for welding of copper using green laser radiation

Selective laser melting (SLM) of pure copper using 515-nm green laser: from single track analysis to mechanical and electrical characterization

In situ alloying: investigation of the melt pool stability during powder bed fusion of metals using a laser beam in a novel experimental set-up

Christoph Spurk's research works RWTH Aachen University, Aachen and other places

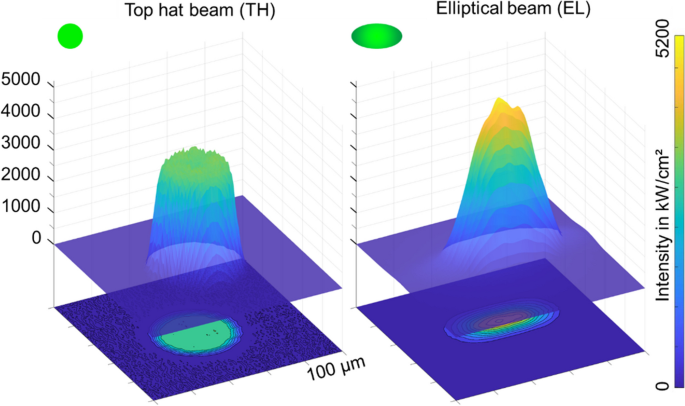

Influence of Laser Beam Intensity Distribution on Keyhole Geometry and Process Stability Using Green Laser Radiation

X-ray video sequence of laser beam welding of copper using 515 nm laser

Influence of Laser Beam Intensity Distribution on Keyhole Geometry and Process Stability Using Green Laser Radiation

High-speed images of fusing threshold (a), heat conduction welding (b)

Florian Kaufmann on LinkedIn: Characterization of Vapor Capillary Geometry in Laser Beam Welding of…

Characterization of dissimilar aluminum-copper material joining by controlled dual laser beam

Florian Kaufmann on LinkedIn: Characterization of Vapor Capillary Geometry in Laser Beam Welding of…

Characterization of dissimilar aluminum-copper material joining by controlled dual laser beam

Schematic arrangement of Michelson interferometer for measuring

Comparison of the melt pool geometries for the different indices and

Schematic of working principles and applications: (a) ultrasonic

Welding depth in dependence of laser power, without oscillation (blue)